Industry 4.0 emphasizes intelligence, connectivity, and digitalization. CNC machine tools are a critical part of this transformation. Connectivity and MonitoringThrough IoT, CNC machines can transmit real-time data, enabling remote monitoring and predictive maintenance. Big Data AnalyticsMassive data from machine operations helps…

Advantages and Limitations of CNC Machine Tools

CNC machine tools are widely adopted for their efficiency and accuracy, but they also come with limitations. Advantages Limitations ConclusionWhile CNC tools have challenges, their advantages far outweigh limitations. Careful planning and integration ensure maximum return on investment.

How to Choose the Right CNC Machine Tool

Investing in the right CNC machine is crucial for manufacturers. A poor choice can lead to wasted costs and inefficiency. Identify Processing NeedsCompanies must first assess material types, part shapes, and accuracy requirements. For example, turning jobs require CNC lathes, while…

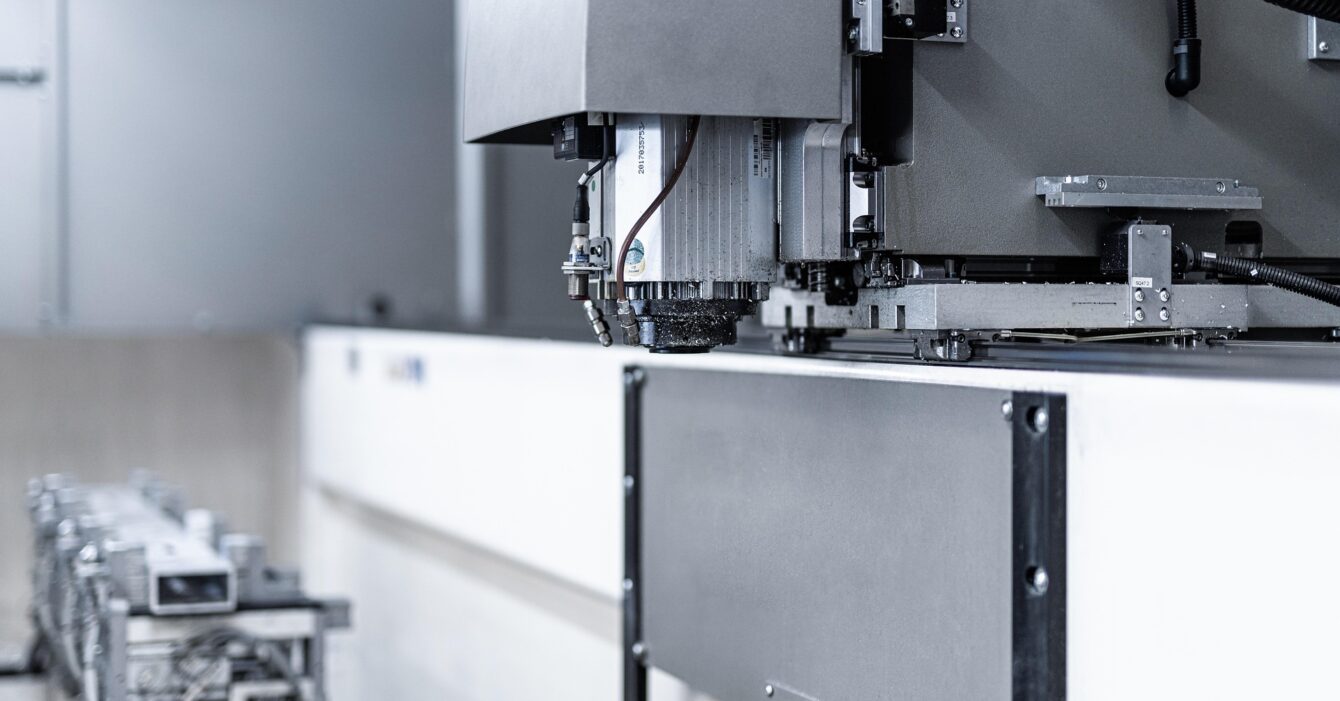

CNC Machine Tools in Aerospace Manufacturing

The aerospace industry demands extreme precision and reliability. CNC machine tools are essential in meeting these strict requirements. Complex Component MachiningAircraft and spacecraft parts often involve complex geometries. Five-axis CNC machines can complete multi-surface machining in a single setup, ensuring accuracy…

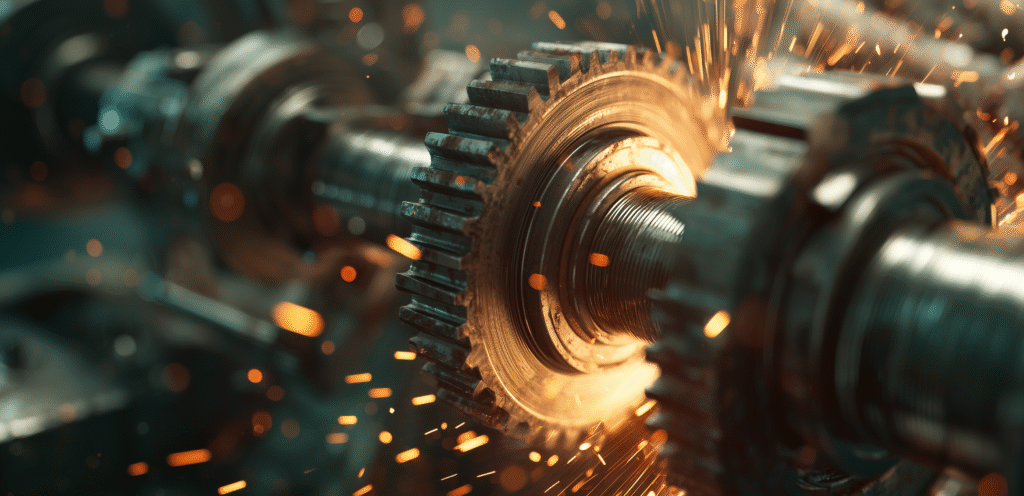

The Evolution and Future Trends of CNC Machine Tools

CNC machine tools (Computer Numerical Control) are the backbone of modern manufacturing. Since their inception in the 1950s, CNC technology has transformed from basic numerical systems to today’s intelligent machining centers. Early StageThe first CNC machines relied on punched cards or…